It’s been a decade since the original iPhone launched, revolutionizing personal computing as we know it. While Apple’s iconic handset changed the way we all interacted with personal electronics forever, it wasn’t perfect. Actually, one element of the phone - its battery life - was positively woeful.

Despite handset technologies continuing to develop at a rapid rate, with flagship phones being replaced year after year by new, superior siblings, the original iPhone’s biggest problem - shoddy staying power - remains in the iPhone 7 and its rivals.

Chipsets continue to get faster, camera megapixel counts continue to go up and ever increasing amounts of RAM and internal storage are squeezed in, leading to remarkable handsets like the Samsung Galaxy S8 and Sony Xperia XZ Premium. Battery life, however, has stagnated at the single day mark, 36 hours max if you’re lucky.

Those pipe-dream promises of week-long batteries we’ve all coveted for the past decade appear no closer to reality than they were that day back in 2007, when Steve Jobs told us all we’d have to charge our phones every night.

Why though are smartphone batteries so slow to develop? We asked a number of industry experts to find out and discover just how far away that perfect smartphone battery really is.

Chasing the impossible dream

Improving battery life shouldn’t be that difficult, right? Just make the battery bigger, or invest some of those billions of dollars of profit that the smartphone space is rolling in to boost battery development. Sounds simple.

Unfortunately, things aren’t that straightforward. Developing a new battery isn’t just about splashing the cash, hiring the best scientists and engineers, or even the passage of time. Unlike advancing processing power, which follows a pre-set path, creating more energy dense batteries requires creating whole new fields of science.

“Processing power tends to follow something we call Moore’s Law, so every few years transistors get slightly smaller and therefore we can fit more onto a chip and get more processing power,” explained Dr. Billy Wu, an Electrochemical Science and Engineering lecturer at Imperial College London’s Dyson School of Engineering.

“In microprocessors, it’s all about making things smaller. In lithium-ion batteries, if you want to get an improvement in energy density, so how long your phone lasts, then you need to fundamentally change the materials that you put inside of it.”

This isn’t as easy as simply switching out certain chemicals in favor of others. Instead it’s a carefully balanced concoction of components that if mismanaged could be seriously dangerous.

“At the moment we use NMCs, those nickel, cobalt, manganese combinations, and in the next few years we’ll have an energy density increase just by tweaking the ratios of the elements we put in,” he explained.

“We will get more energy by putting more nickel inside because it’s a more reactive element. That will happen in the next few years. We are slowly solving it.

“These progressions, we’re using the same materials so can slot that into the same manufacturing lines right now as we use the same equipment. That will give you an order of maybe 10 or 20% extra performance.”

A 10-20% improvement in battery life is nothing to be sniffed at, that will edge you into the realms of two days between trips to the mains rather than nightly charges. Years of development for just one additional day of battery life isn’t exactly the advancement consumers are demanding though.

Why battery life isn't a quick fix

Progress is slow, and as much as the industry and consumers alike are calling out for batteries with a higher energy density, the wait will continue for some time yet.

“Battery manufacturing is a bit of a dark art,” Dr. Wu told us. “The reason why it takes so long is that people have to try every single combination of things. We want increasing amounts of lifetime, so to get that certainty, we have to test.”

Even when suitable substitute materials have been found, things are still never as simple as a straight swap.

“Silicone is seen is as a replacement for graphite in our batteries, and that has ten times the energy density as graphite as it is, so imagine your phone lasting ten days instead of one day,” Dr. Wu teased. “The problem there is that we have a huge volume expansion.”

He explained: “As we charge and discharge our batteries, graphite actually expands and contracts by about 10%. We can handle 10%, but silicone when you charge it and discharge it actually expands by 300%, so you can imagine a 1 meter wide battery pack for your electric vehicle suddenly becoming 3 meters wide, which just isn’t practical.

“We need to deal with some of the engineering challenges there.”

Money is also a sticking point when it comes to battery development. Not the money being pumped in, there’s plenty of that, but with potentially billions to be made off a breakthrough, there are hundreds of manufacturers, scientists and research groups looking to crack the next big step change.

With no pooling of resources and a profits-first view on the development, a lack of industry-wide collaboration is again hampering progression.

“There is a lot of R&D going on around people experimenting with new battery technologies,” George Paparrizos, Qualcomm’s Product Management Director in charge of battery management told us.

“A lot of them are in the early stage and it usually takes a few years from an R&D project to being manufactured.”

When are we due a significant step up?

So, when will that coveted week-long smartphone staying power finally become a reality? Well, unless you’re happy to plump for the new Nokia 3310 over the upcoming iPhone 8 or next-gen Samsung Galaxy, sadly not anytime soon.

“It takes roughly about 10 years and £100 million to develop a new chemistry, so the economies of scale aren’t comparable with microprocessors,” Dr. Wu said.

This is just phase one, too, with a lengthy development period followed up by another decade needed to get these new technologies safe and stable for widespread commercialization.

He added: “Each time you make a new chemistry, it takes about 10 years to commercialize that. If you look back at the original patent for the lithium-ion battery, it was first published in Oxford University in 1980. Sony first commercialized it in the 1990s.

“On the horizon we have other chemistries that will take a bit longer. People are talking about substituting sulphur into the battery or silicone and behind that, something called a lithium-air battery which is seen as the holy grail. That will take more than a decade or two before we perfect it.”

Just because new battery chemistry is still a long way off doesn’t mean advancements aren’t being made, however.

Filling the void

While a generational change in battery technology is still some way off, smartphone battery lives are improving, albeit very slowly.

Incremental improvements are being made, and regularly, but with increasingly power-hungry components such as expansive QHD displays, these are largely only helping smartphone manufacturers tread water in terms of overall staying power.

It’s not just battery experts that are looking to optimize performances of current technologies either. Smartphone manufacturers and component suppliers are also going to extensive lengths to eke out every available percentage point from the batteries currently available to them.

“Whilst innovation in battery life is always a long-term goal, we have been focusing on making the power consumption of our products more efficient,” a HTC spokesperson said, speaking exclusively to TechRadar.

“The HTC 10 for example features a PowerBotics system that improves the phone’s hardware and software efficiency to deliver up to 30% longer battery life by auto-detecting and shutting down apps that use excessive power.”

With the wait for a step change in battery technology expected to be a lengthy one, this managing of expectations and optimizing efforts looks set to continue.

They added: “Software such as HTC Sense Companion has also been incorporated to let users know in advance if they are running out of power based on their consumption and personal schedule, and we see this technology developing in the coming years.”

HTC is far from alone in this pursuit. While rival smartphone manufacturers are all finding ways to extend the battery life of their devices, component suppliers such as chipset maker Qualcomm are also working on solutions.

“Qualcomm is doing a number of things. The Snapdragon 835 is the first processor to use the new 10nm technology. Every time you push the processor technology forward, you have less leakage and a much more efficient operation inside the system,” Paparrizos explained.

“Every year we improve at taking battery power and converting it to system power. Our goal every year is to become more and more efficient at doing that.

“If you look at the efficiency improvements, it’s always going to be incremental numbers because you can only be up to 100% efficient eventually.”

The dangers of battery experimentation

There’s another stumbling block in the road to the perfect smartphone battery, a big one at that - safety.

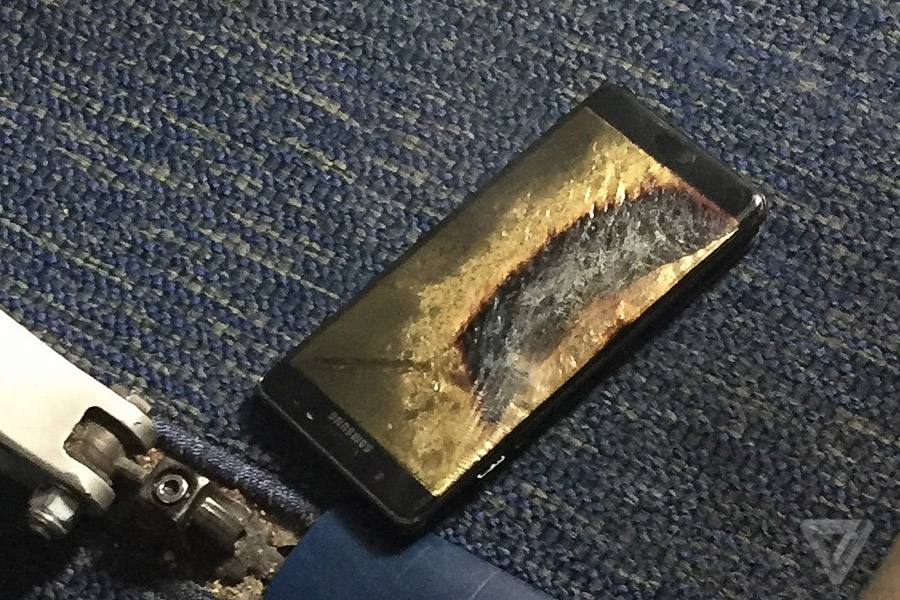

The difficulties in experimenting with battery technology were drawn into sharp focus last year as a result of the Samsung Galaxy Note 7 fiasco. After a number of power units exploded, the phone was hit with a global recall. Changes were made but the explosions kept coming, an aggressive battery design was to blame and a second, permanent global recall was issued.

With the phone banned from aircraft over safety concerns and Note 7s responsible for burnt out cars and minor owner injuries, it has caused the entire industry to take a cautious look at the need to squeeze every single percentage point out of the battery units.

“As we put more energy in the battery, it inherently gets more unsafe,” Dr. Wu told us. “As we are doing this, we have to keep an eye on will it explode, which has obviously been something of a topical discussion point with the Samsung Galaxy Note 7 batteries.”

The Note 7 issues were more than a PR disaster, they could further slow the progression as manufacturers are forced into being increasingly cautious.

“The Note 7 incident did bring more attention to the battery. We don’t always see how OEMs use the batteries, certain people might have pushed it more than others,” Qualcomm’s George Paparrizos added.

His comments were backed up by Dr. Wu, who added: “I would hazard a guess that they tried to push the envelope for energy density a bit too much without considering the safety. It is one of the key concerns and it is potentially one of the things that could hamper battery technology.”

While Samsung’s issues have reverberated around the entire industry, the manufacturer itself is already looking to move past the well-publicized problem, most notably with the Samsung Galaxy S8, a phone that has somewhat cautiously switched to a rather conservative 3,000mAh battery.

“It was a very newsworthy item, so it’s not something that people will forget,” Samsung’s European Head of Product Management, Mark Notton told us recently.

“Certainly, with the announcement that we made back in Seoul, and what we talked about at MWC, hopefully we’re able to close that chapter and move on.”

The future of smartphone development

While your annual chipset bumps and camera tweaks are set to continue - manufacturers have to offer something new - smartphone batteries will catch up. Soon? No. But the focus being heaped on them continues to grow.

“Battery is one of the focus areas of the industry,” Paparrizos said. “If you look at all of the technology in the phone, battery is the one that’s lagging. Every time a technology is lagging, people focus on it and eventually bring it up to match the rest of the stuff.”

Battery technology will be forced to catch up. It won't be anytime soon, but it will happen. Until then... can I borrow your charger?

- Can't wait for a better battery? You could always get a phone with a bigger one.

from TechRadar: Phone and communications news http://www.techradar.com/news/the-impossible-dream-perfecting-smartphone-battery-life

No comments:

Post a Comment